The printed circuit board plays an essential role in almost every sector of the economy. You can find circuit boards in cars, smartphones, medical devices, and several other electronics products. PCB assembly is the manufacturing process used to manufacture PCB. Furthermore, the current innovation in manufacturing ensures that the PCB is small in size. The small size requires various aspects for it to be attained. Thus, this article will inform you of six elements of the PCB assembly service.

Six aspects of PCB assembly service

1. Designing of PCB

The first feature in the PCB assembly service involves expressing the PCB idea via the PCB design folder. The purpose of the design is to ensure that manufacturers have an exact idea of how the PCB will look like after production is complete. Furthermore, the PCB design should cover essential parameters such as copper weight, silkscreen, layer count, solder masks, board interconnections and several others.

2. Prototyping

Prototyping is crucial in testing whether the PCB design is fit for mass production. The PCB assembly service ensures that quality and lead time are a priority when developing the prototype. Furthermore, for mass production to occur, the prototype needs to be deemed quality and efficient.

3. Fabrication

In PCB assembly service, PCB fabrication is an essential aspect. PCB fabrication ensures that a sturdy electronic connection foundation is established. The fabrication element consists of several steps that are consistently upgraded due to the changing requirements in the market. Furthermore, PCB manufacturers are expected to conform to the ever-changing fabrication requirements.

4. Assembly

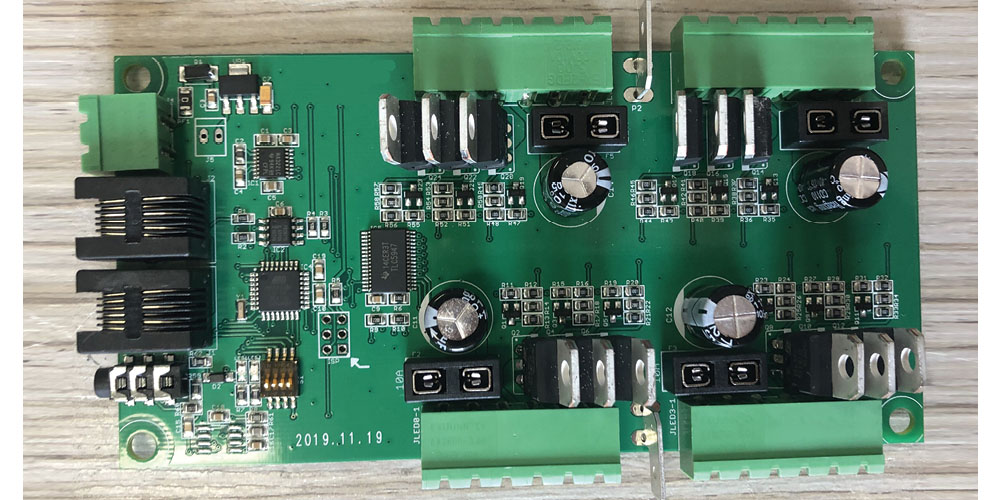

One other aspect of the PCB assembly service is PCB assembly. The assembly process happens after fabrication is completed. The purpose of this aspect is to increase the PCB board connection range with other components. Furthermore, there have been innovations made in the assembly process, ensuring affordability and automation of procedures. The recent development in PCB assembly is the Surface Mount Technology.

5. Repair and rework

In the PCB Assembly service, the repair is only a small section. The minor PCB repair and rework section are because most PCBs developed using the best technology require little reworking because of their high quality.

6. Sourcing

In the PCB assembly service, the PCB sourcing element covers a broad definition of features. They include; components sourcing, copper foil sourcing, and material sourcing.

Services offered by the best PCB manufacturers

- Low cost and high efficiency: The best PCB manufacturers ensure that they manufacture the PCB at minimal prices. Furthermore, they also provide to offer assistance in design creation.

- Flexibility in volume: The best manufacturers in the market are flexible in their production, meaning they can produce both high volumes and low volume PCB prototypes.

- Fabrication and Assembly services: The best manufacturer available in the market ensures that they offer you all the services you need. The services should also meet your every requirement.

- Components sourcing: The best manufacturer should include components sourcing as part of the services they offer. Furthermore, they should have an excellent relationship with components manufacturers, thus, guaranteeing 100% quality.

Conclusion

The various aspects of the PCB Assembly service ensure that all the manufacturing processes are carried out effectively. Furthermore, the services also ensure that the PCB produced has met all the set standards.