Ultra High Molecular Weight Polyethylene, also referred to as UHMWPE, is a material that has found extensive applications in industries that require stability, predictability and longevity in service. Although the price of UHMWPE products seems to be higher initially compared to other conventional plastics or metals, an extended analysis will reveal that UHMWPE is unmatched by others in terms of long-term value. The uhmwpe is a smart and economical investment option in industrial use when it comes to measuring cost to lifespan, maintenance, and performance.

Understanding the Initial Cost of UHMWPE

UHMWPE is usually more expensive to purchase initially than other materials like HDPE, nylon, or ordinary steel materials. This is because it is manufactured in a complex procedure and requires high material characteristics. UHMWPE is designed to be considered incredibly wear-resistant, very impactful and low-friction, and it is inherently high-end. But purchase price alone may be a deceptive factor to look at, since it does not represent the entire lifecycle cost of the material.

Exceptional Wear Resistance and Longevity

Another major benefit of UHMWPE is that it has excellent abrasion and wear resistance. UHMWPE parts are much more durable than others in applications that require continuous sliding, impact and abrasive materials. This long life duration lowers the rate of replacement of parts, and thus the downtime and the cost of labor are minimized. The decreased frequency of replacements counterbalances the increased start-up cost, and in the long term, UHMWPE would be more economical.

Reduced Maintenance and Downtime Costs

The ability of UHMWPE to lubricate itself and have low friction facilitates smoother and more efficient operational of equipment. UHMWPE does not need to be lubricated frequently like metal components, and it does not accumulate materials that may lead to jamming in the system or failure. Minimization of maintenance also means cutting down operating costs and minimizing downtime, which is very important in the mining industry, material handling industry, construction industry and chemical processing industry. These savings become constant over the life of the equipment.

Impact and Chemical Resistance Benefits

UHMWPE has a high impact strength at low temperature conditions, when most plastics are brittle. This strength will not crack, deform, or cause unexpected failures, causing expensive repairs and safety hazards. Moreover, UHMWPE is very resistant to chemicals, oils and solvents. It also has a long service life in corrosive environments where metals are likely to rust or deteriorate, further decreasing the cost of replacement.

Long-Term Cost Efficiency

Lifecycle cost is high when comparing materials to be used in an industrial context to the initial costs. The high service life of UHMWPE, coupled with very low maintenance, means that the total cost of ownership is lower. Companies enjoy increased productivity, reduced closures and stability. UHMWPE can be much more cost-effective over a period of a few years of operation as compared to low-cost materials, which need frequent repair or replacement.

Versatility and Customization Value

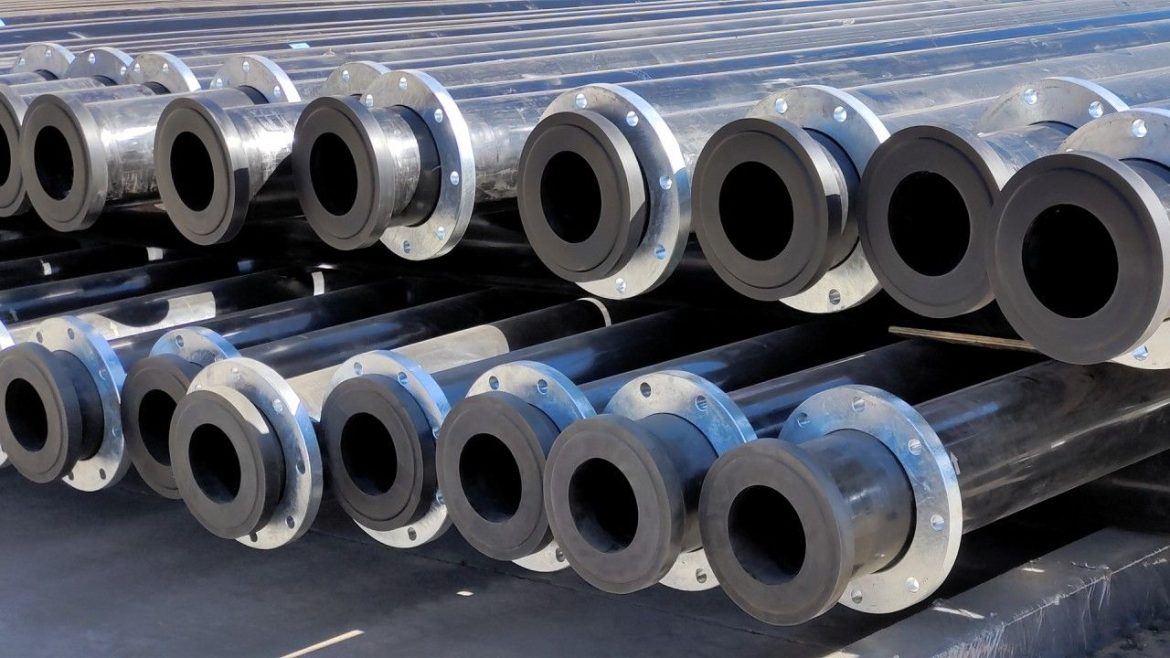

UHMWPE is a material that is easily machined and engineered to fit the needs of particular applications. Individual sheets, rods, pipes, and wear parts enable businesses to maximize performance and minimize wastage of materials. This flexibility ensures that UHMWPE solutions are accurately aligned with the operational requirements, enhancing efficiency and service life. Customization also increases the ROI by providing an improved performance at reduced sacrifices.

Additional Long-Term Value of UHMWPE

Along with its resistance to wear and tear, UHMWPE has provided the benefit of long-term life by its versatility and flexibility in applications across a broad spectrum of industries. It is easy to machine, and hence components can be accurately designed to meet the operational requirements, enhance the efficiency of the system, and minimize wastage of materials. The custom UHMWPE parts are usually more compatible, durable and represent better performance as compared to the standard ones. The reduction in costs is even more advantageous in the long term. This customization, reliability and longevity create a blend that guarantees the continued payback of investments in UHMWPE long after the initial purchase and is therefore a good long-term business material.

Conclusion

Although UHMWPE might incur a greater initial purchase price, its great longevity and functionality make it a good long-term investment. Less wear, less maintenance, the ability to resist impact and chemicals, as well as longer service life, all lead to great savings in the long run. UHMWPE has always been a better value proposition when it is considered in terms of lifecycle costs. UHMWPE is an efficient, strong, and cost-effective material that can be considered by industries that need high-quality materials that can withstand high demands.