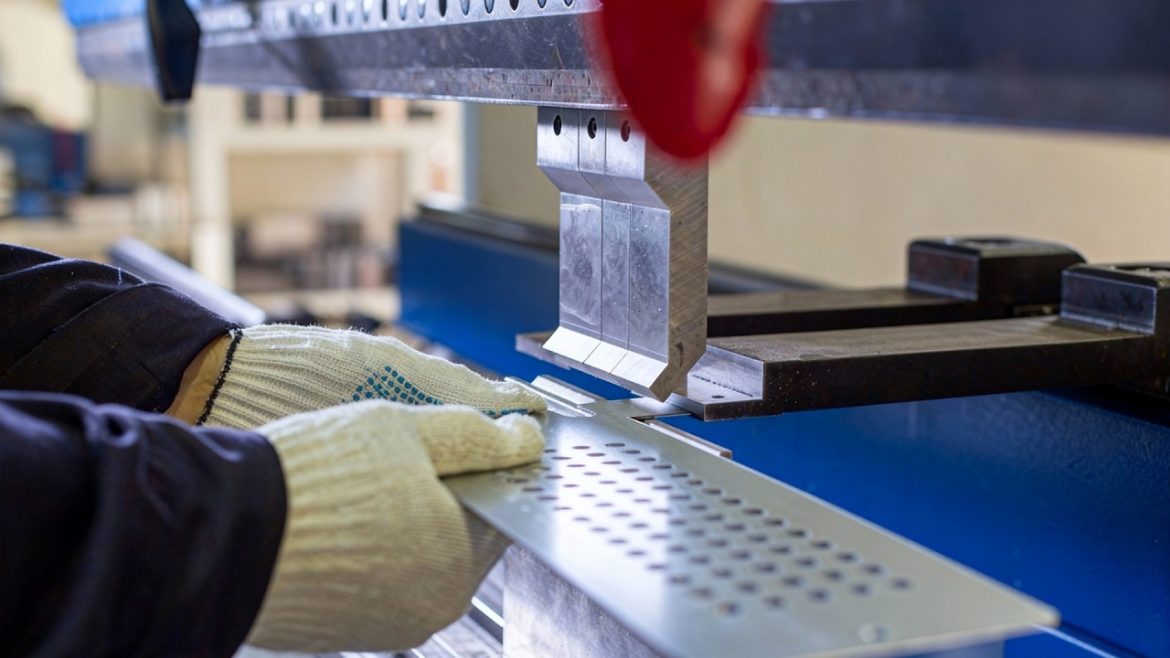

Features of sheet metal fabrication include bending and forming. These operations influence the level of part fit, assembly fit and the real performance of a product. The result of poor control in bending may be gaps, stressing points and reworking in assembly. ShincoFab specializes in precision bending and forming services, which provide true angles, clean radii, and repetitive outcomes in prototypes and manufacturing production runs.

The Role of Bending in Sheet Metal Structures

The majority of metal enclosures, frames, brackets and chassis are started as flat sheets. These flat blanks are made into rigid three-dimensional parts by controlled bending. A bend is a source of strength and a delineation of the connection of the part to the rest. A slight error in the bend will cause the drift of mounting holes or even panels not to lie flat. This is why bending is considered to be a controlled manufacturing process in contrast to a mere shaping operation.

Equipment That Supports Accuracy

ShincoFab uses CNC press brake systems to maintain tight control over bend angles and positions. These are machines that have programmable back gauges to position every bend line accurately. Tooling is picked according to the type of material, thickness and radius needed. The alignment of the punch and die set to the job minimizes marking of surfaces and provides consistency of the geometry of the bend. Calibration of the machine is done on a regular basis in order to provide consistency. This is significant where components are required to be made in batches over time, and it still needs to be similar to previous deliveries.

Managing Material Behavior During Forming

Metal varies across alloys and thicknesses. Springback, where material partially reverts after bending, is considered. ShincoFab adjusts bend settings to ensure final angles match. Grain direction is also considered when laying out blanks. Bending across or along the grain can change strength and risk of cracking, especially in harder materials. By planning bend orientation early, forming defects are reduced, and part durability improves.

Achieving Consistent Bend Radii

The inside bend radius influences both strength and appearance. Too small a radius can cause cracking, while too large a radius may interfere with assembly. ShincoFab selects tooling that produces the specified radius while maintaining structural integrity. For visible parts such as external panels or medical device housings, surface quality around bends is monitored closely. Proper die selection and clean tooling help avoid scratches and pressure marks that would affect the final finish.

Complex Multi-Step Forming

Some components require multiple bends at different angles and directions. The sequence of these bends affects final accuracy. ShincoFab plans to take steps to prevent interference between already formed flanges and the tooling. This sequencing reduces cumulative error and keeps overall dimensions within tolerance. For deeper forms or shapes beyond simple bends, additional forming techniques may be used. These processes are integrated with standard bending so that parts move smoothly from one operation to the next without unnecessary handling.

Tolerance Control in Bending Operations

Dimensional control is a key part of precision forming. Back gauge positioning, angle measurement, and in-process checks help maintain tolerances. Test bends are often performed at the start of a job to confirm settings before full production begins. When parts include features such as slots or holes near bend lines, their positions are verified after forming. This ensures that bending has not introduced unacceptable distortion. Maintaining these checks reduces assembly problems later.

Supporting Downstream Assembly

Well-formed parts simplify welding, fastening, and final assembly. Square corners, consistent angles, and accurate flange lengths help components align without forcing. This reduces stress in welded joints and improves overall product quality. ShincoFab coordinates bending with other fabrication steps, such as hardware insertion and surface finishing. Planning these interactions prevents issues like coating damage at tight bends or misalignment of inserted fasteners.

Applications Across Industries

Precision bending and forming are used in many sectors. Electronics enclosures depend on tight bends for panel fit and electromagnetic shielding. Machinery frames rely on formed sections for stiffness. Medical devices use formed stainless steel for clean, rigid structures. Aerospace interiors and support structures also require lightweight parts with accurate geometry. Consistent forming practices allow ShincoFab to serve these varied needs while maintaining quality standards.

Continuous Improvement in Forming Processes

Processing data from previous jobs helps refine future setups. Feedback from inspection and assembly teams is used to adjust tooling choices and bend allowances. Over time, this reduces setup time and improves first pass accuracy. The goal is not only to meet specifications but to do so reliably across different projects.

Conclusion

The workings of the sheet metal parts are determined through precision bending and forming before the final assembly. Control of equipment, tooling, material behavior, and inspection is necessary to assure that every bend serves to strengthen the structure and has dimensional accuracy. ShincoFab utilizes the disciplined forming techniques in manufacturing parts that fit, assemble and work as planned under hard-working conditions.