The mission to create power transmission models that are efficient and compact has led to tremendous improvements in belt technology in modern automotive engineering. It includes a V Ribbed Belt, a poly-V belt, and a serpentine belt, which have become an important element in high-torque automotive engines. These belts are designed to be flexible, strong, and durable, and serve a very important role by transmitting the crankshaft’s power to various accessories, including the alternator, power steering pump, and air conditioning compressor. Not only does their high design enhance performance, but it also guarantees long life reliability under high-torque engine conditions.

How to Design V Ribbed Belts

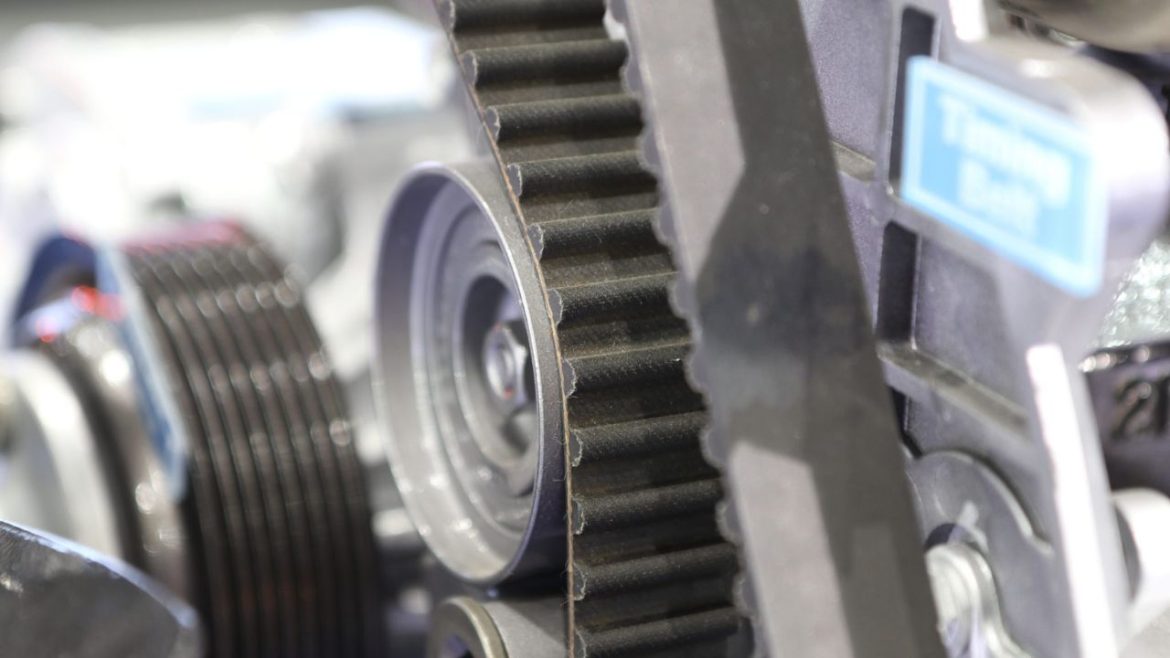

V ribbed belts are named like such due to their multi-ribbed design. The rib itself is of a V shape and fits into the grooves of an appropriate pulley. This design enhances the area of contact between the pulley and the belt, and allows effective transmission of power without much slippage.

This is unlike the traditional V belt, in which there is only one wide groove; the V ribbed belts have many smaller ribs that run the length of the belt. These ribs evenly spread the load and enable working more easily, including in the case of using several accessories at the same time.

Improved Power Transmission Efficiency

Among the biggest advantages of V ribbed belts in automotive engines that have high power is their unsurpassed power transmission efficiency. The multi-ribbed design provides more surface area of contact with the pulley, leading to a lower loss of energy through slippage or friction. This enables the belt to pass on a higher torque more efficiently than the standard V belts or flat belts.

With several systems that are being driven by a common belt, like the alternator, cooling fan, and supercharger in high-performance engines, it is important to ensure that power delivery is consistent. V ribbed belts perform well in this part by offering stable and efficient transfer of torque over a big span of engine speeds.

Small-Block Designing of New Engines

The auto makers are also trying all they can to produce engines that are smaller and lighter yet do not affect the amount of power the engine is capable of producing. V ribbed belts are made to fit well in these new and compact layouts, and this is because of the slim and flexible design.

V ribbed belts have the advantage of being able to power more than one accessory using a single unit of a belt system, and this is often referred to as a serpentine drive system. This not only occupies less space, but also eases the engine design with the replacement of a number of individual belts by one continuous belt. The outcome is a more compact and easier-to-service power transmission system that results in a higher level of engine reliability.

Reduced Vibration and Noise

Reduction of vibration and noise is another important benefit of the V ribbed belt in high-torque automotive systems. The repeated contact of several ribs with the pulley grooves offers a smooth and constant engagement, which minimizes the effects of belt whip and vibration that may be caused in traditional belt systems.

This dampening of vibration helps in making the engine operations quieter, especially in the passenger cars that focus on comfort. In addition to that, the balanced loading of the ribs in many makes the wear less and the belt and pulley last longer, which leads to increased reliability and reduced maintenance requirements.

Strength in Adverse Environment

Powerful automobile engines produce high levels of heat, and they are generally subjected to extreme operating conditions. V ribbed belts are also pushed towards extreme conditions such as high temperature, oil exposure, and continuous tension changes. These belts are good since they use advanced rubber compounds and reinforced cords, which ensure that the structure and flexibility of the belts are upheld in case of extended use. The ribbed profile also aids in the dissipation of the heat more efficiently, lowering the chances of glazing, cracks, or premature crashing.

Easy Maintenance and Prolonged Servicing

Most of the modern vehicles have a serpentine belt system, which runs on a V ribbed belt, making it much easier to maintain. Rather than having several belts to fit various accessories, one V ribbed belt has the capability of driving all parts, which only minimizes the quantity of parts that require replacement or adjustment. In addition, the belts have fewer tension adjustments since they can automatically adjust to the optimal tension by use of tensioners.

Conclusion

The V ribbed belts have transformed the transmission of power in high-torque automotive engines. Their new ribbed design is superior in grip, very efficient, and smooth in its operation, even in harsh conditions. They allow present-day engines to provide solid performance in a small area, and they have the capacity to be portable and consequently last long without compromising on fuel efficiency and reliability.