Warehouse management happens whenever large items and loads are being carried throughout a facility with the use of human or controlled industrial devices, allowing them simpler to move, preserving goods from harm, as well as sparing you from moving and handling expenditures.

Resource transportation, like a cargo lift, allows employees to better organize freight, improve efficiency, and provide a safe workplace. Most industry areas employ lifting devices, including retail store showrooms, factories, and industries.

Versatile process control devices can allow things to move freely around a structure. All you’ll need are workers who understand how to use them and which is ideal for the task.

A lazy waiter, commonly known as a dumbwaiter, and a trolley lift are included in the utility lift category. These light-duty platforms may move everything from business and medical devices, espresso, meals, and beverages to tiny objects, kegs, and huge crates, with load capacities ranging from 50 kg for mini lifts to 500 kg for precision cart lifts. They can be found assisting numerous types of businesses for this reason.

Cargo lift

There’s the option of bigger equipment movers. In commerce and industrial business, cargo lifts and rack lifts with a weight capacity ranging from 3000kg are used to transfer heavy stock products and commodities.

They may be delivered as a stand-alone framework and are capable of transporting big goods across multiple levels. Most have bump buffers, a sloped mechanism, and interlocking doors to prevent loads from moving about inside the platform.

There are also cargo-assisted lifts available, which provide the added benefit of carrying your items with two observers.

Heavy Items and Passengers Lifts

Transportation, airplane runways, clinics, and commerce are all good candidates for using heavy-duty lifts. Such lifts have higher capacity and more durable coatings, allowing them to transport heavy gear, healthcare and emergency supplies, theater and scenic gear, and sometimes even vehicles and airplanes!

Pallet Truck

A pallet truck is a wheeled and manual lifting equipment for moving and carrying pallets. The device can lift, transport, and lower any item from point A to point B by using the bent prongs underneath the platform and the hydraulic lever. It’s commonly used to transport merchandise around factories, stockrooms, and retail stores worldwide.

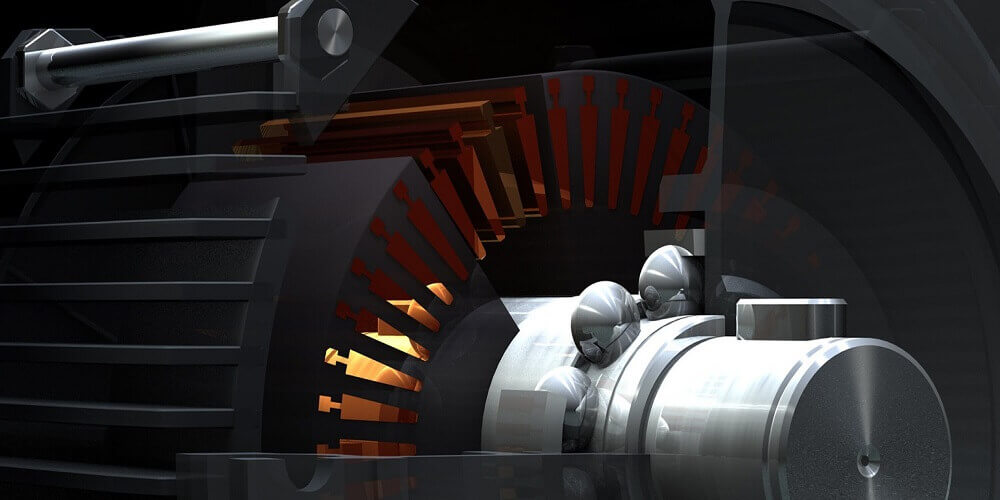

Forklift truck

Pallets, big items, and supplies are moved with the forklift truck. They are employed in warehousing, factories, manufacturing areas, and building sites because of their durable structure, length, and load-bearing capacity.

Bridge cranes and lifting winches

In warehouses and industries, lifting hoists and bridge cranes are employed. A bridge crane is constructed up of consecutive poles with a traveling bridge spanning the distance; the lift is the component that helps hold, raise, and move the superstructure. There are several types of cranes and lifting equipment available, ranging from human to motorized, as well as hoisting hoists that assist the old or crippled.

Conveyor belts

You might think about moving sidewalks when you think of the above. They’re comparable in that they smoothly convey big amounts of goods, cartons, and commodities down a long runaway/belt, helping corporations to send and receive more merchandise with smaller locations and lower labor costs.